FloodWarden TECH

The FloodWarden Tech automatic flood barriers complement the comprehensive FloodWarden offer which also includes composite and aluminum barriers FloodWarden LITE and FloodWarden PRO.

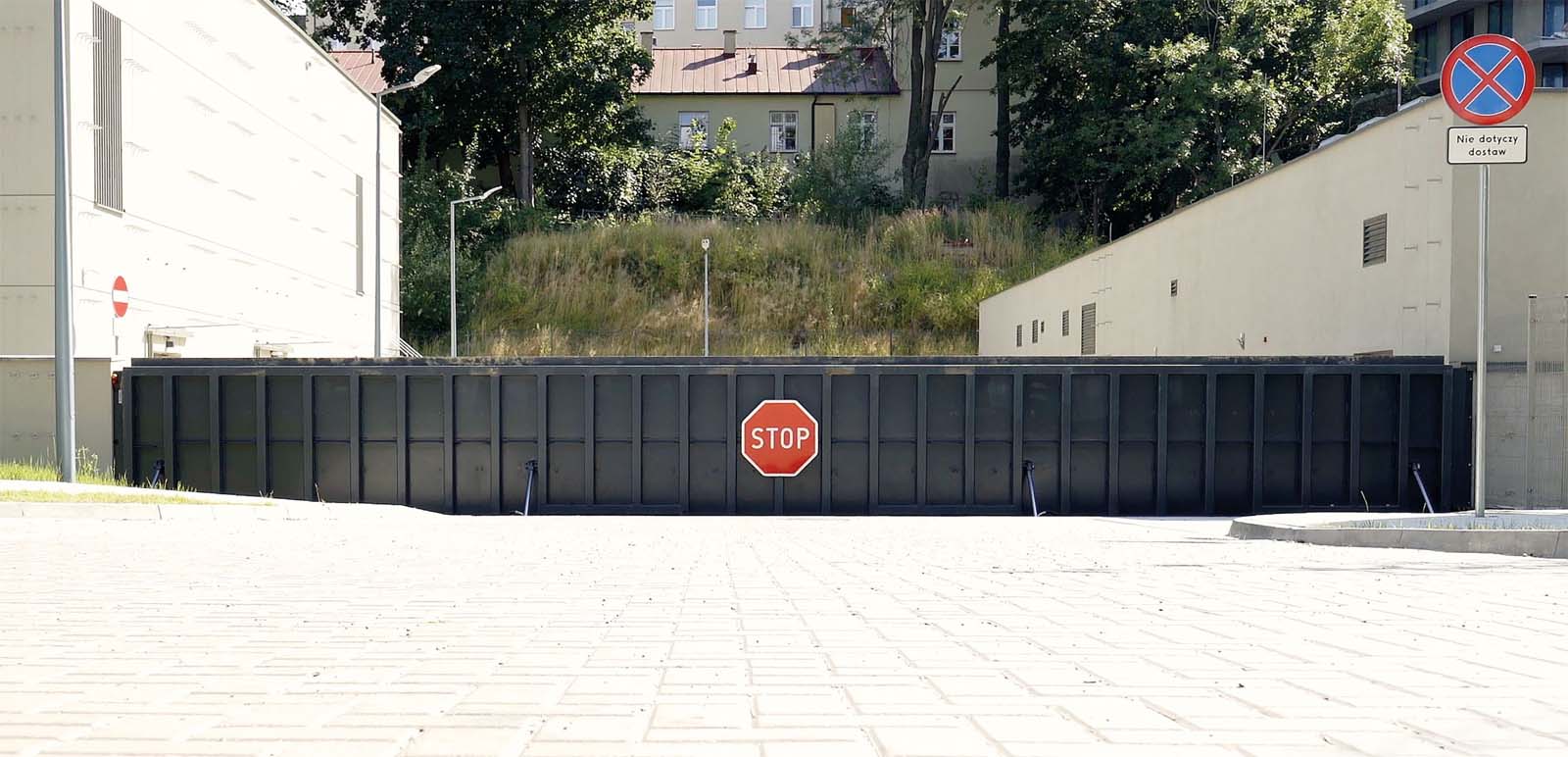

FloodWarden barriers ensure undisturbed pedestrian and vehicular traffic during periods when water poses no threat.

In the event of a flood threat, the sensor system automatically triggers the barrier closing protocol.

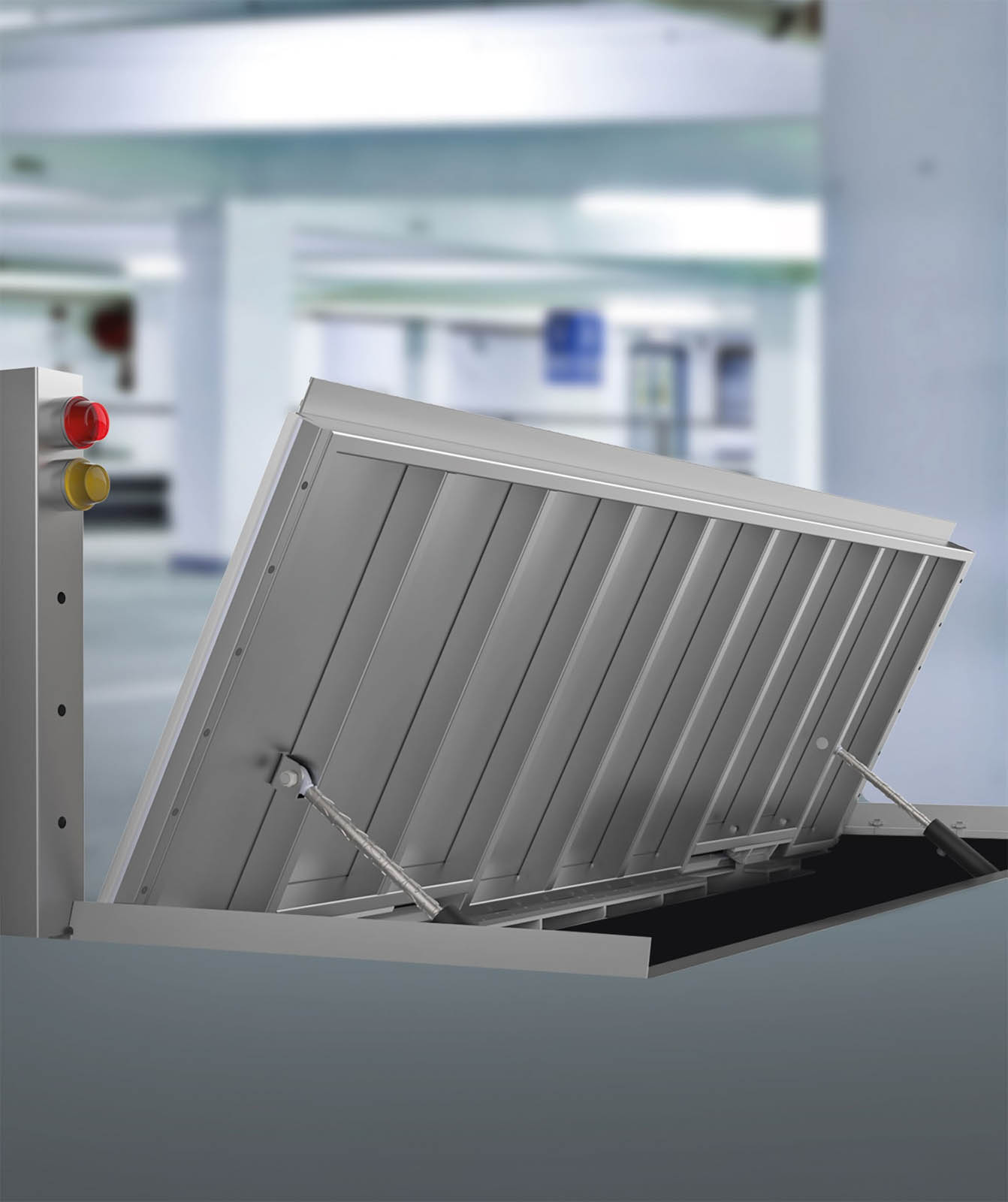

The closing of the barrier and the red signal are always preceded by an orange signal indicating a flood threat.

Each barrier is equipped with a separate alerting scheme installed at the steel profile.

SIGNALS

OPTIONAL EQUIPMENT

Sensors monitoring the current status of surface water and automatic emergency self-lifting of the barrier.

Motion sensors and weight sensors, which prevent the barrier from lifting when a vehicle is driving-by or parking or a pedestrian crossing.

Emergency lever, allowing manual lifting of the barrier.

Platform grate, security protecting the recess when the barrier is raised.

Wireless installation, designed for continuous monitoring of the current position of the barrier.

- Barriers designed and manufactured according to the highest quality norms and standards.

- Frame structure, lifted by a dedicated independent hydraulic system.

- 120 seconds is the maximum time required for all barriers to fully close.

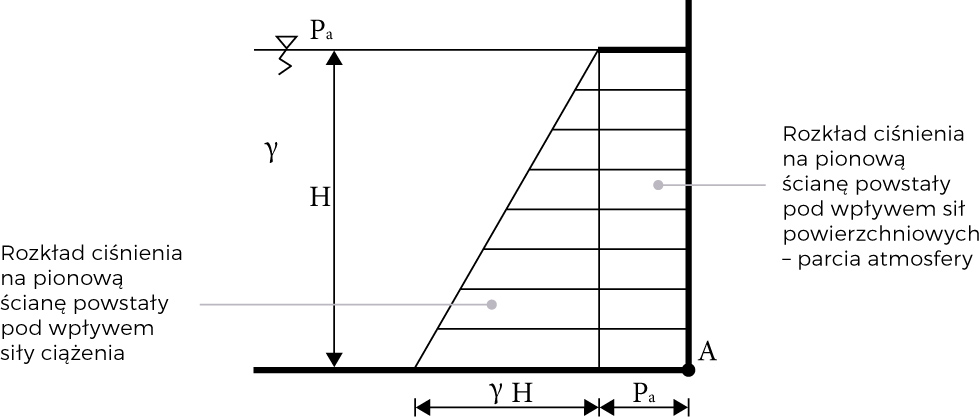

- The VRG seal ensures tightness of the barrier. The system is ultimately tightened under the water pressure. Special covers protect the sealing elements and the hydraulic mechanism during non-emergency periods.

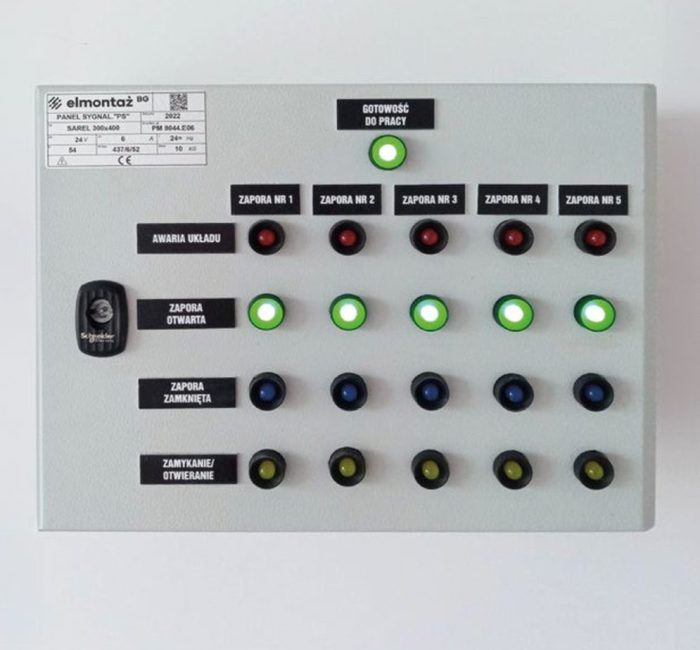

- The current status of the barriers is monitored by end switches. Information is displayed on the light panel installed in the control room of the Building Management System (BMS).

- The working surface of the barrier is made of non-slip, stainless steel checkered plate. The color scheme of the visible external elements is adapted to match the requirements of the project.

- In special cases, e.g. during repairs and maintenance, each barrier can be closed individually using buttons on the control and distribution boxes installed at the unit casing.

- In the event of a power failure, the hydraulic installation is equipped with PMI type manual pumps. The units are installed in steel cabinets and only trained personnel have access to them.

tytul

- Trzy podstawowe typy systemów zapór z możliwością dostosowania wymiarów oraz trybu działania do indywidualnych potrzeb klienta i obiektu.

- Możliwość indywidualnego dostosowania szaf sterujących, zasilających, systemu monitoringu i sygnalizacji

- Integracja ze złożonymi systemami zarządzania nieruchomościami.

- System FloodWarden Tech jest projektowany i produkowany zgodnie z normami jakości i standardami bezpieczeństwa.

- Każda zapora opuszczająca fabrykę przechodzi wymagające badania jakościowe i testy działania.

- Zapory FloodWarden Tech wyposażone są w sygnalizację dźwiękowo-świetlną, ostrzegającą o każdorazowym uruchomieniu systemu.

- System posiada niezależny układ siłowników, agregat hydrauliczny oraz awaryjny manualny system podnoszenia zapory, które zapewniają działanie w przypadku braku zasilania lub awarii.

- Specjalnie zaprojektowana uszczelka VRG gwarantuje szczelność zapory a przy naporze wody doszczelnia cały układ.

- Układ uszczelnienia i hydrauliki chroniony jest w trakcie normalnego użytkowania zapór specjalnymi osłonami.

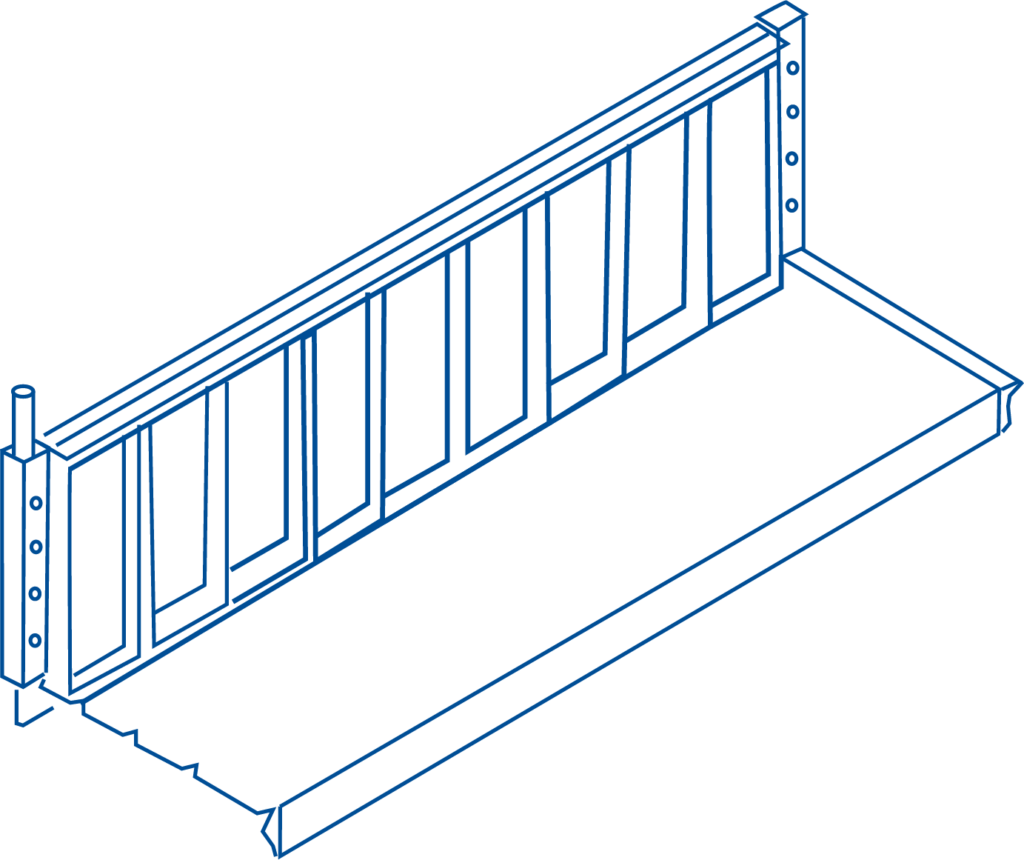

THREE TYPES OF BARRIERS WITH THE POSSIBILITY OF FURTHER CUSTOMIZATION

The FloodWarden Tech system consists of three basic models of flood barriers, which may be additionally adapted to comply with the individual requirements of the property and its surroundings.

The barriers may be fully customized in terms of their dimensions and purpose. Specific system elements may be tailor-made, including control can power supply cabinets, monitoring equipment and signaling sensors. FloodWarden Tech can be integrated into the property management systems.

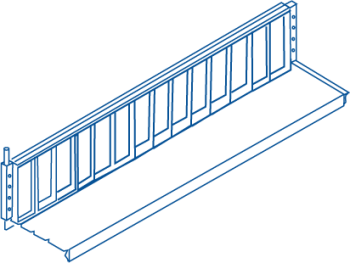

FLOODWARDEN TECH STANDARD

| DIMENSIONS | Maximum length: 6000mm Maximum height: 2000 mm |

| PURPOSE | pedestrian, vehicular traffic |

| MAXIMUM LOAD | vehicles with a permissible total mass of up to 3.5 t. |

| BARRIER COATING (RAL 7035) | platform – stainless steel |

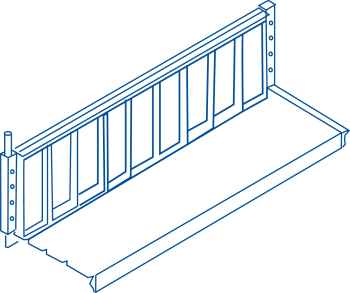

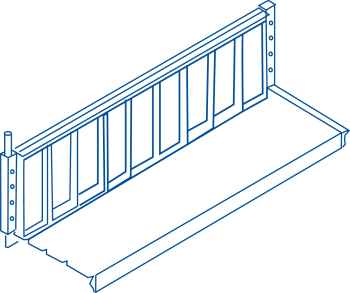

FLOODWARDEN TECH XXL

| DIMENSIONS | Maximum length: 15000mm Maximum height: 2000 mm |

| PURPOSE | pedestrian, vehicular traffic |

| MAXIMUM LOAD | vehicles with a permissible total mass of up to 3.5 t. |

| BARRIER COATING (RAL 7035) | platform – stainless steel |

FLOODWARDEN TECH HEAVY

| DIMENSIONS | Maximum length: 15000mm Maximum height: 2000 mm |

| PURPOSE | pedestrian, vehicular traffic |

| MAXIMUM LOAD | vehicles with a permissible single drive axle load of up to 11.5 t. |

| BARRIER COATING (RAL 7035) | platform – stainless steel |

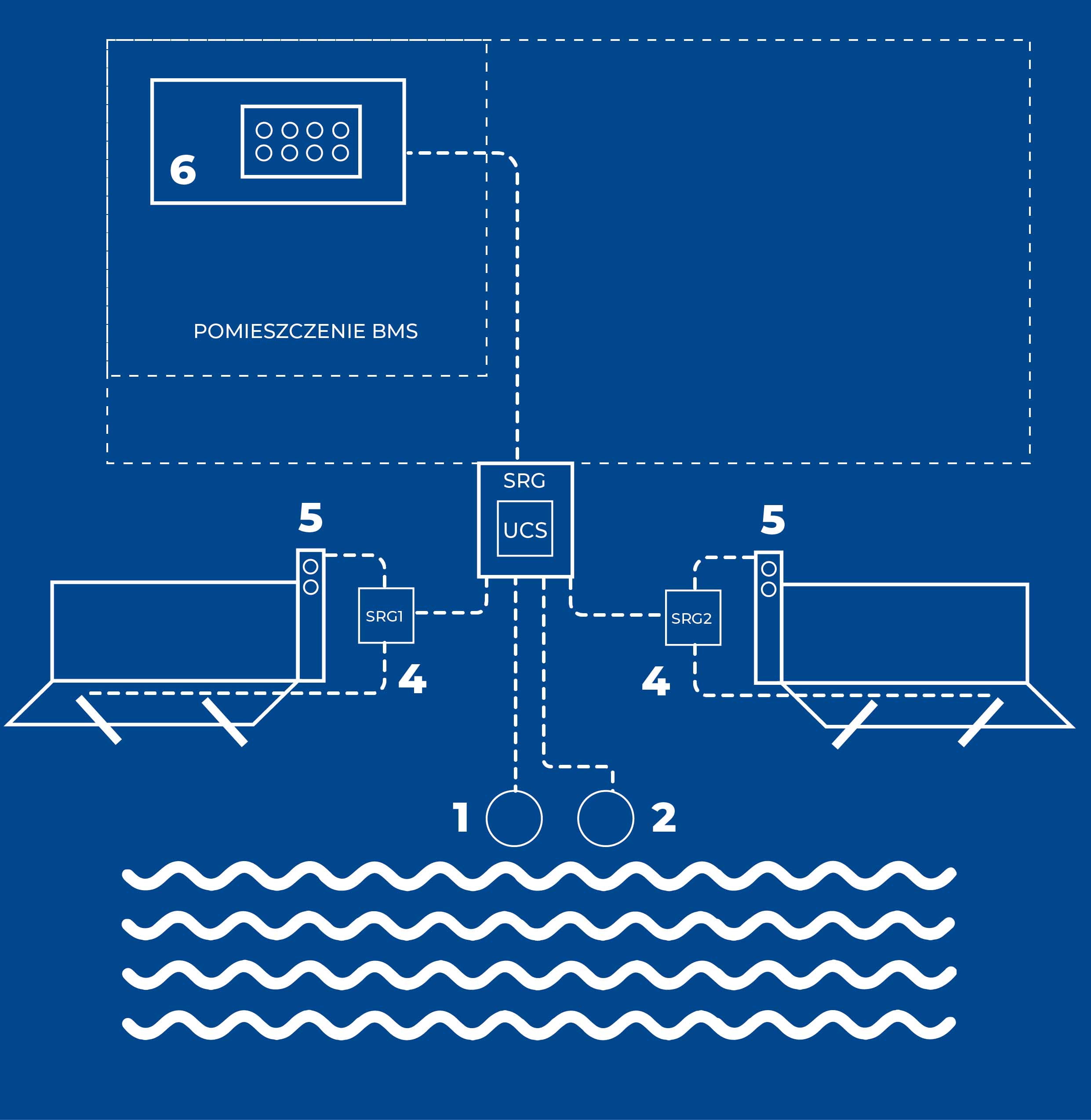

HOW DOES FLOODWARDEN TECH BARRIERS WORK?

- The water level is monitored with measuring probes installed in the immediate vicinity of the water.

- If the water level reaches the emergency level, the measuring probe SP-0 alerts the main controller, then to the BMS room – FLOOD WARNING

- As the water level rises, when the emergency level is exceeded – probe SP-1 / 2 activates the controller which sends an emergency alert to the BMS room – FLOOD EMERGENCY

- At this point, the flood barrier is activated with an audio-visual signal and the message: BARRIER LIFTING

- The position of the barriers is continuously monitored by end switches and the controller with all alerts displayed on the signaling panel, usually installed in the BMS room.

- The system is ultimately sealed under the pressure of water.

- The water level drops below the emergency level.

- The barrier automatically lowers to its initial position.

DIAGRAM OF OPERATION

- SP1 measuring probe

- SP2 measuring probe

- the main control and distribution box with CCS – Central Control System

- distribution and control box contains: – SRG 1/2 – hydraulic pump

- voice signaling unit

- visual signaling unit

SP – signaling panel (installed in the BMS room)

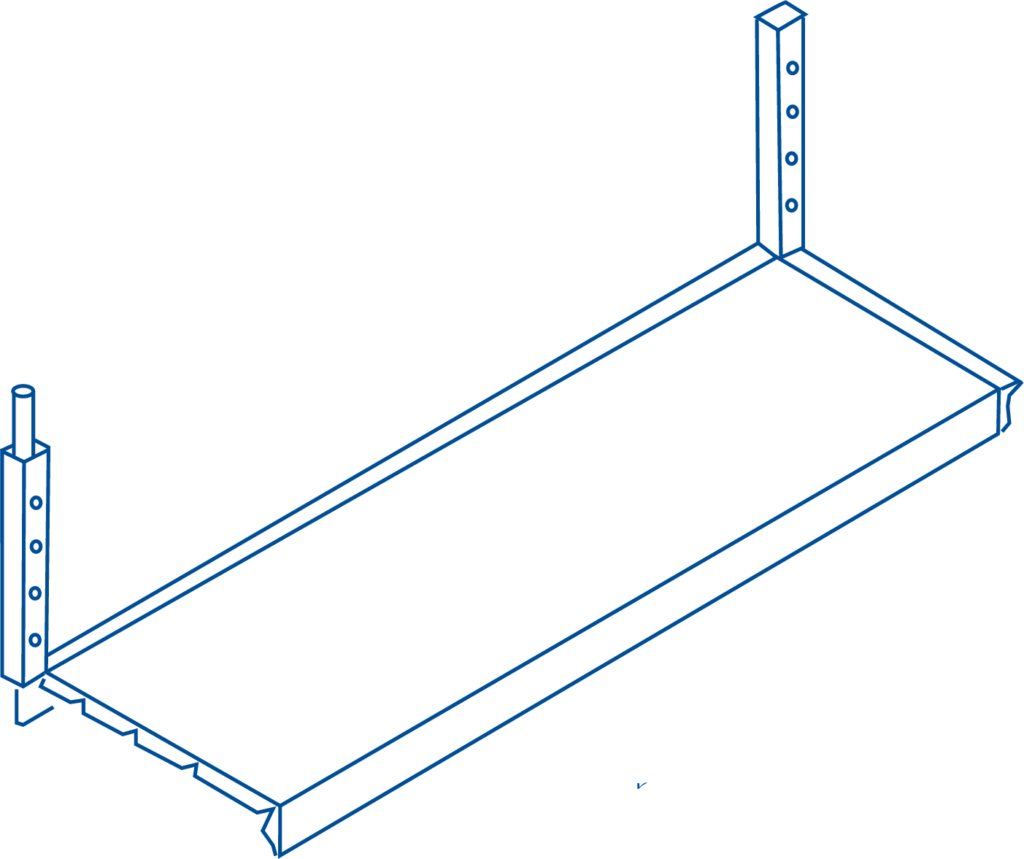

MONTAŻ ZAPÓR

Zapory FloodWarden Tech montowane są specjalnie w przygotowanych w tym celu żelbetowych nieckach montażowych.

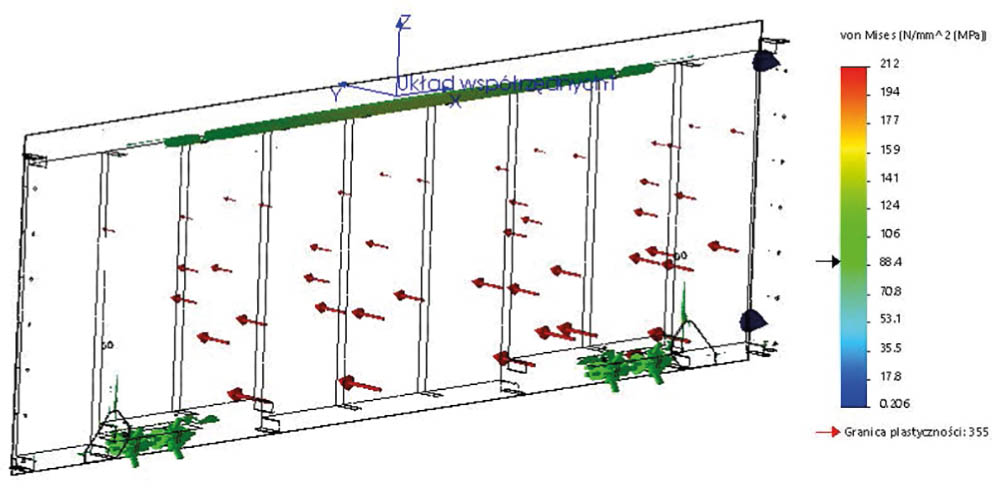

Trwałość zmęczeniowa do maksymalnego naprężenia*

*134 MPa – dla zapory STANDARD dobierając odpowiednią kategorię zmęczeniową). Wyniki przedstawiono w formie wykresu liniowego, zgodnie z normą PN-EN 1993-1-9:2007/NA:2010.

FloodWarden Tech barriers are covered by the Factory Production Control System and are manufactured and distributed according to the ISO standards:

FloodWarden Tech barriers are covered by the Factory Production Control System and are manufactured and distributed according to the ISO standards:

ISO 9001:2015, ISO 45001:2018, ISO 45001:2018